Annie Ding, Mary Millard

Abstract:

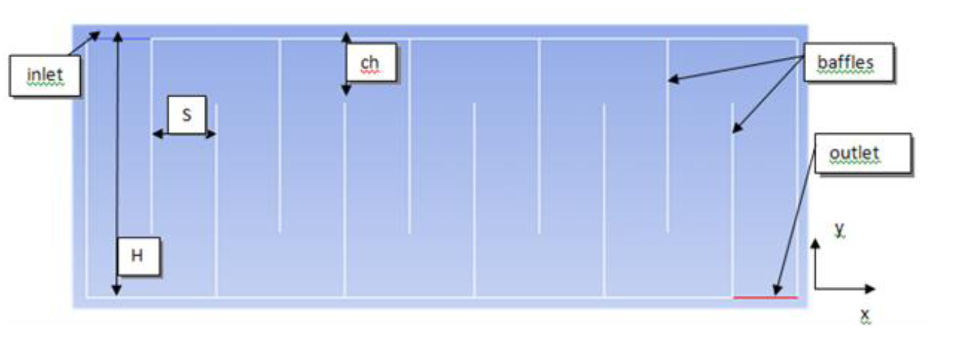

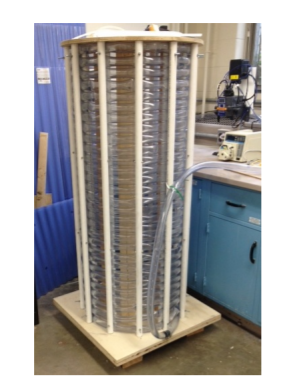

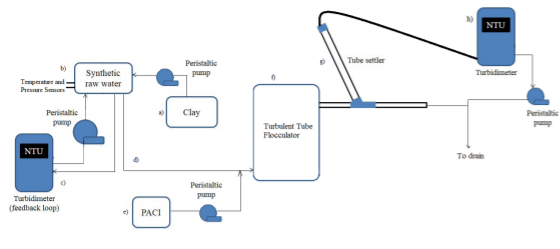

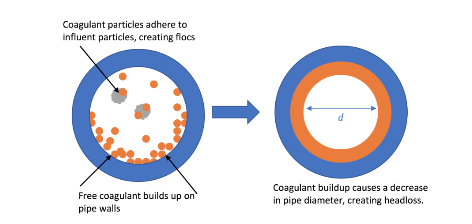

The current AguaClara plant design requires a large entrance tank to settle out grit particles prior to the flocculator. Grit removal by horizontal flow sedimentation prevents the settling of these larger particles in the flocculator (a phenomenon that has been observed in several AguaClara plants to negatively affect plant flow and operation). The purpose of the Grit Removal Innovation Technologies (GRIT) team is to redesign the current grit settling system by introducing plate settlers prior to the flocculation unit. In doing so, the plan-view area needed to settle out the grit will be greatly reduced, decreasing construction costs and overall AguaClara plant size. This paper outline the GRIT team’s process exploring plate settler design options that act either as sedimentation units only, or as combined flocculation and sedimentation units.

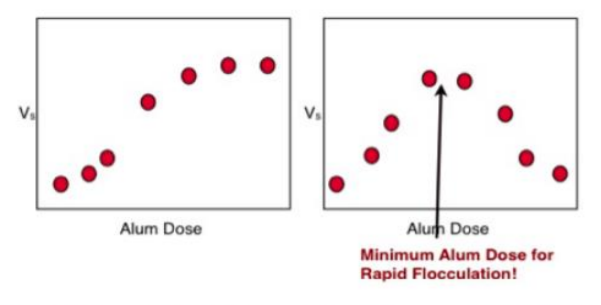

There is no other literature on the topic of designing such grit removal systems, and not all of the relevant parameters are well understood. The team’s design process has therefore been based on a series of reasonable assumptions and equations currently used in flocculator and sedimentation tank design. Many constraints (detailed in this report) were found to impact the design of the grit removal unit, including grit particle “roll-up” effect, optimal head loss, optimal unit length. In addition to the design of the grit removal unit itself, this team explored the corresponding designs of rapid mix, linear flow orifice meter (LFOM) placement, and coagulant dosing, in order to create a fully integrated system.

Over the course of the Spring 2015 semester, the GRIT team has developed three potential grit removal designs, created visual mock-ups of each, and even sent a detailed design of the best iteration to Honduras for implementation in a small-scale plant. The first iteration, a combined grit removal and flocculator system, integrated grit removal capabilities into the flocculator baffles, but it was rules out early in our design process due to the potential loss of coagulant to grit (as coagulant would be dosed before grit would be removed), inefficient use of space, and construction and cleaning impracticalities. The second and third iterations were both based on the idea of creating a tightly packed series of plate settlers (we call this a Grit Removal Unit, or GRU), analogous to the ones used in current sedimentation tank design, used before the flocculation process and designed to settle out grit specifically. The second iteration placed this GRU inside the entrance tank, while the third iteration placed it within the first flocculator channel. After analyzing space need, flexibility of design, and capacity for rapid mix/coagulant dosing integration, the third iteration was chosen as the optimal grit removal design and is well on its way to being constructed in Honduras!