Tami Chung, Alexander O’Connell, Karen Swetland

Abstract

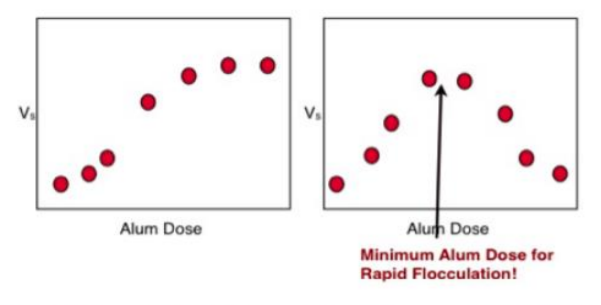

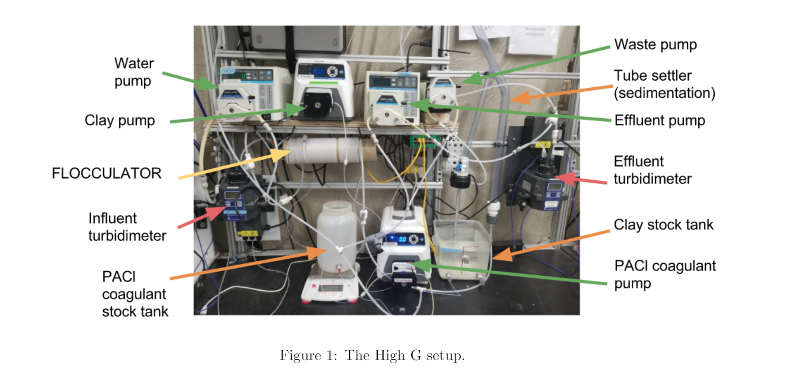

The Fall 2010 Tube Floc Team of aimed to better understand the development of rapid flocculation through a series of experiments and data analysis. In previous semesters, we had focused on the variation of flocculator length and alum dose. With the completion of these studies, we encountered more questions regarding the fundamental mechanisms involved in the process. As a result we chose to focus on characterizing the minimum coagulant dose needed to initiate rapid flocculation for two difference coagulants, alum and PAC. We hope to use this data in the future to develop a theoretical framework describing the onset of rapid flocculation. In order to accomplish this goal and to ensure the accuracy of our data we made a number of improvements and modifications to the FReTA apparatus this semester. We are currently in the process of collecting data and hope to complete our planned experiments by the end of the Fall 2010 semester.