Surya Kumar, Christine Leu, Amlan Sinha, Cindy Dou

Abstract

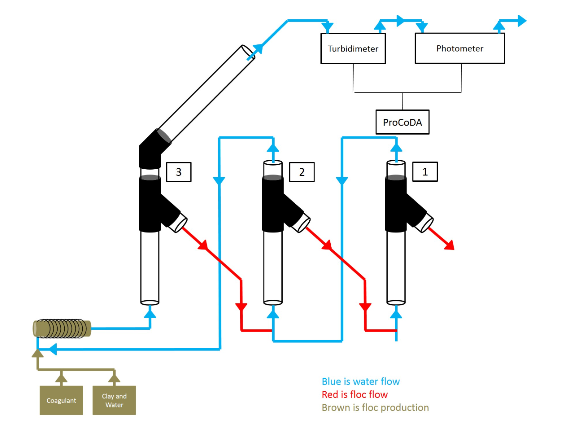

Floc blankets, which are suspended layers of highly concentrated flocs, have the potential of being a more efficient option for removing arsenic, fluoride, and certain dyes in terms of energy and water consumption than currently employed techniques. For floc formation, a coagulant needs to be added to the water, allowing particles to adsorb to each other when they collide. Previous research has shown that the coagulant, polyaluminum chloride (PACl), has properties that allow arsenic, fluoride, and certain dyes to adsorb to its surface. The first iteration of this research used three floc blankets in series with a counter-current flow of contaminated water and flocs. By feeding flocs from the last reactor into the second, and from the second into the first, the PACl’s surface area can be saturated. To test this theory and apparatus, a dye, Remazol Brilliant Blue R (RBBR), was chosen to be the contaminant due to its less toxic nature and visual component. With this apparatus and contaminant, this semester’s goals were to test dye removal efficiency from water with varying concentrations of clay, PACl, and dye. With a 1:1 ratio of PACl to dye, a dye removal efficiency of roughly 80% was achieved. However, the transportation of flocs from the third reactor to the second and first was not sustanaibly achieved.