Jacqueline Dokko, Javier Espada Fraile

Abstract

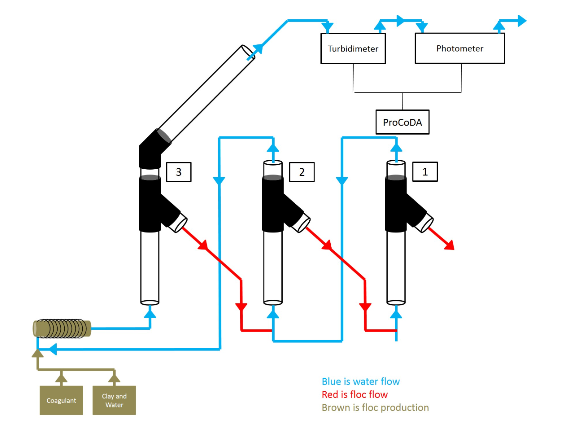

The countercurrent stacked floc blanket reactor is a system for removing suspended solids or dissolved dyes by coagulating them into larger lumps of particles referred to as flocs using opposing currents to run clean water one way and floc-ridden water the other way. Using two standardized reactors, dye and coagulant concentrations, and flow rates, the team worked towards determining whether multiple reactors in a series is more efficient than a single, long reactor. With the known mechanism and the result of the previous research, this semester’s goal was to intensify dye removal by modifying the design of the reactor, system flow path and flow rates. For the future, the flocculator will be modified to be longer allowing larger flocs to form, increasing efficiency of the system as a whole since the discrepancy in flocculator size prevented comparable performance between the single reactor system and the system of reactors in series.