The Effect of Floc Roll-up on Clay-Aluminum Hydroxide Flocs

Matt Hurst, Monroe Weber-Shirk*, Tanya Cabrito, Cosme Somogyi, Michael Adelman, Zachary Romero, Richard Pampuro, Rachel Phillipson, Sarah Long, Colette Kopon, Ying Zhang, Ashleigh Sujin Choi, Adela Kuzmiakova, Jae Lim, Alexander Duncan, Christine Catudal, Elizabeth Tutunjian, Ling Cheung, Kelly Kress, Tiara Marshall, and Leonard W. Lion

Abstract:

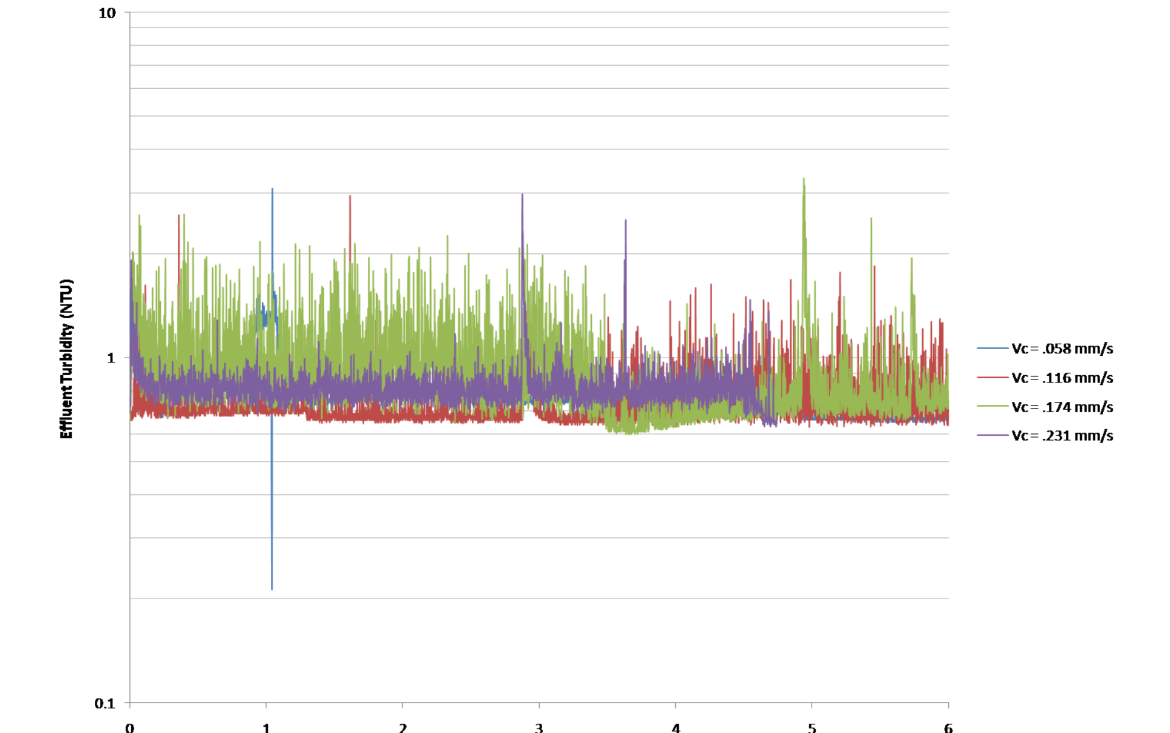

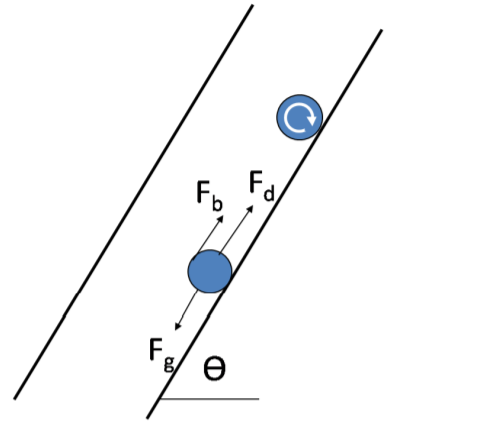

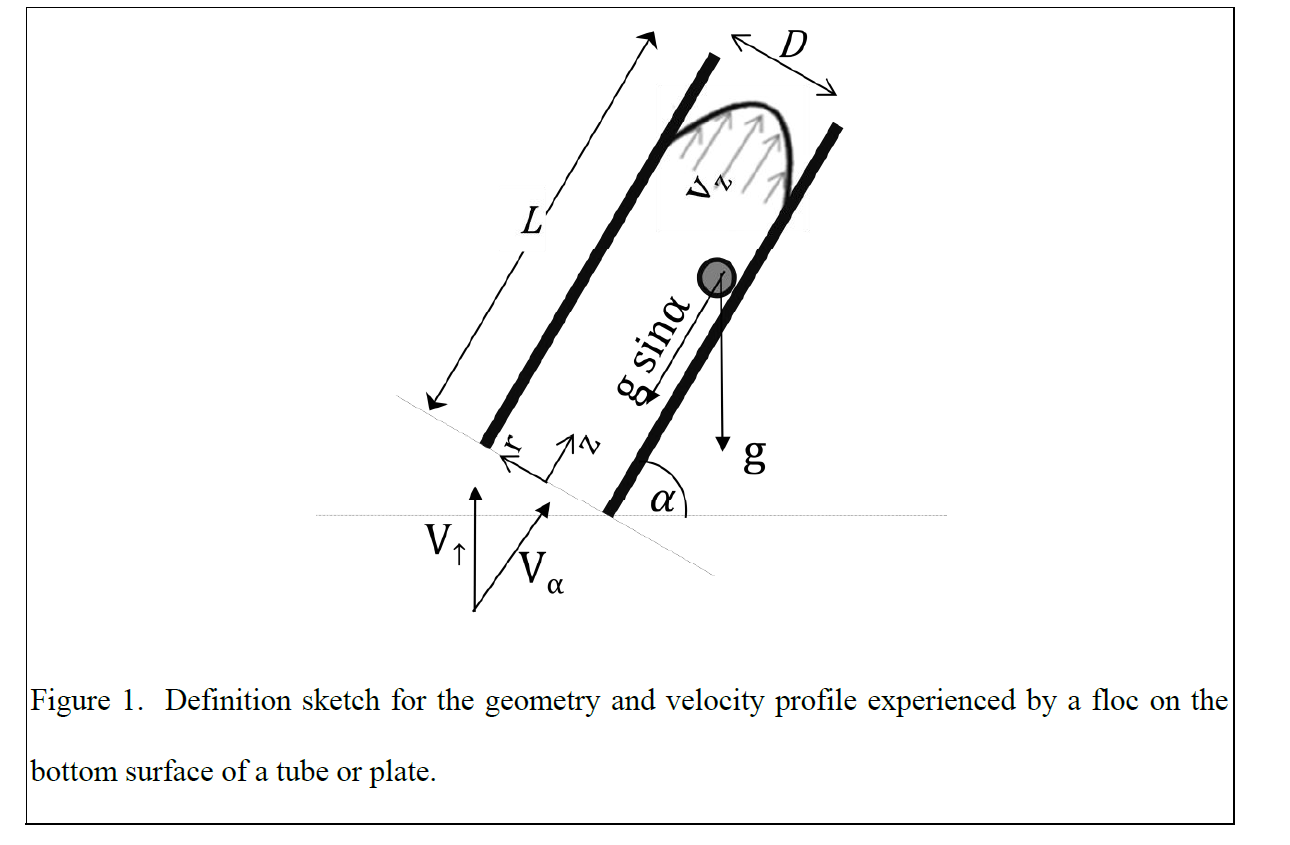

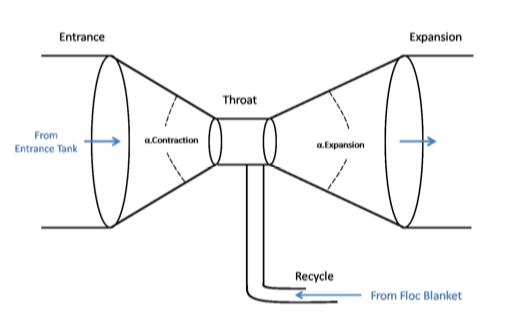

Inclined plate and tube settlers are commonly used to create compact sedimentation tanks. Conventional design guidelines are based on obtaining a desired sedimentation design capture velocity. Theoretically, this capture velocity can still be achieved while greatly reducing conventional plate spacing or tube diameter. The greatest concern with small plate spacing is the danger of settling sludge being swept out with the finished water. This research presents the basis of this failure mechanism as high velocity gradients present at small tube settler diameters and small plate settler spacings.