Abstract

Accurate alum dosing is vital for plant operation as it has a great impact on the effectiveness of flocculation and sedimentation. The nonlinear chemical dose controller (CDC) is designed to handle turbulent flow chemical dosing used in conjunction with the newly designed Rapid Mix Tube. In contrast, the linear CDC requires that the chemical flow in the dosing tube is laminar.

The linear CDC uses the linear relationship between laminar flow and major losses in the doser tube to maintain a constant chemical dose with varying plant flow rates. However, when the flow in the dosing tube is turbulent, the linear relationship no longer exists. In this case, a nonlinear CDC, one that uses minor losses to control flow rates, can be used to maintain a constant chemical dose with the varying plant flow rates. By using an orifice to control chemical flow, the CDC will have the same nonlinear response to increasing flow as the plant flow rate, which is controlled by an orifice. A dual scale system on the lever arm will increase accuracy in dosing at smaller doses.

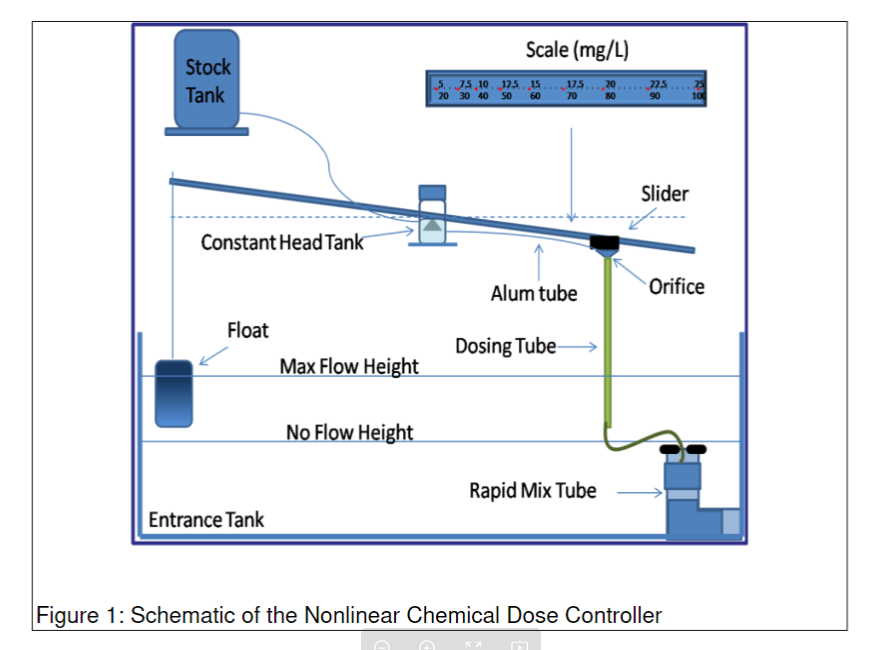

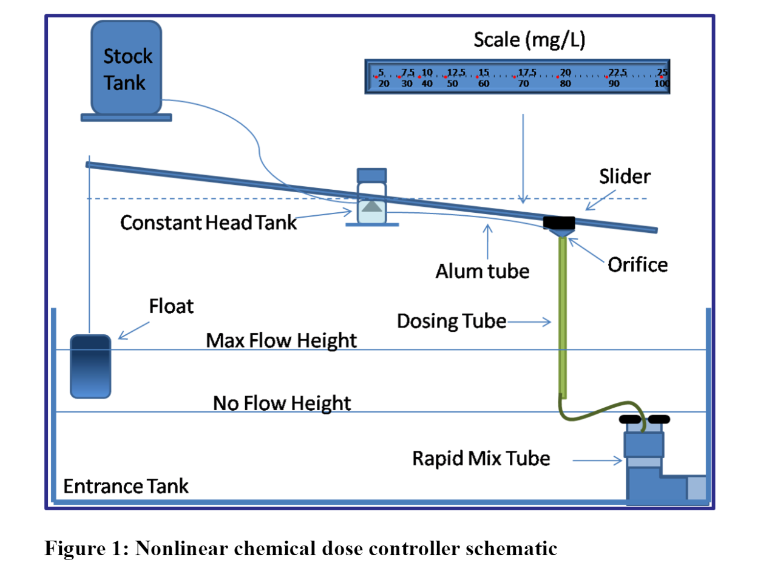

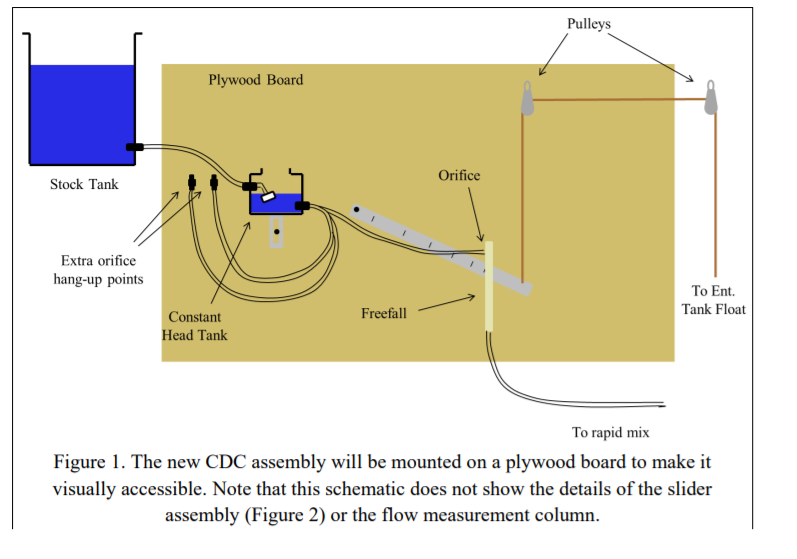

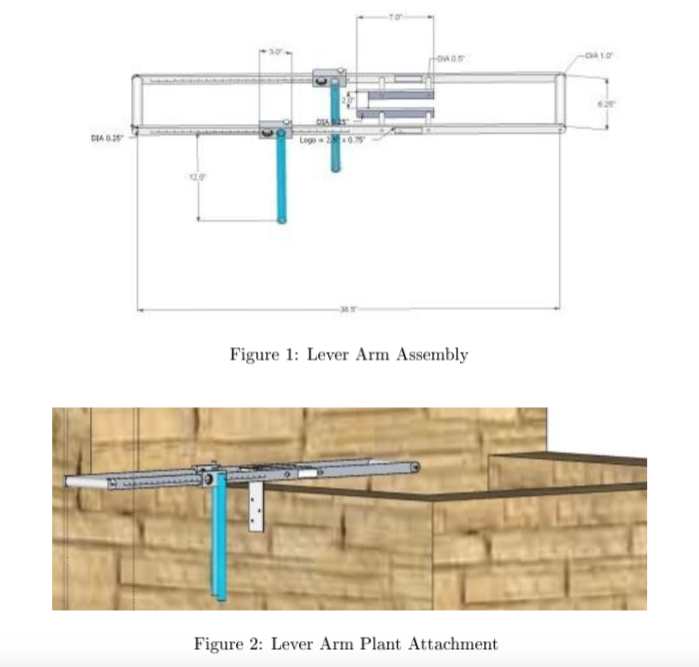

Figure 1 shows a conceptual design of the dosing system. A float in the entrance tank is connected to one end of the lever arm and allows for the arm to move up or down based on varying plant flow rates. As plant flow rates increase, the float rises, and the lever arm connecting the dosing orifice falls increases the elevation difference between the constant head tank and dosing orifice to power chemical flow. As the flow rate decreases the elevation difference decreases and the chemical flow rate slows down.

Figure 1: Nonlinear chemical dose controller schematic

There are two dosing tubes coming out of the constant head tank each with a different size orifice fitting attached to the end. The two different sized orifices allow for the plant operator to dose alum at two different scales, a high and low scale. The operator will choose which orifice will be used based upon the desired alum dose the operator wishes to apply to the water, a parameter that depends on raw water characteristics. The two scales on the lever arm, as seen in Figure 1, correspond to one of the dosing tubes; for instance, the higher scale (20-100 mg/L) will be used when the larger orifice size is needed. The dosing tube which is not in use is merely lifted to a higher elevation than the constant head tank level and is clipped onto a hook to prevent the flow of alum through this unused orifice.

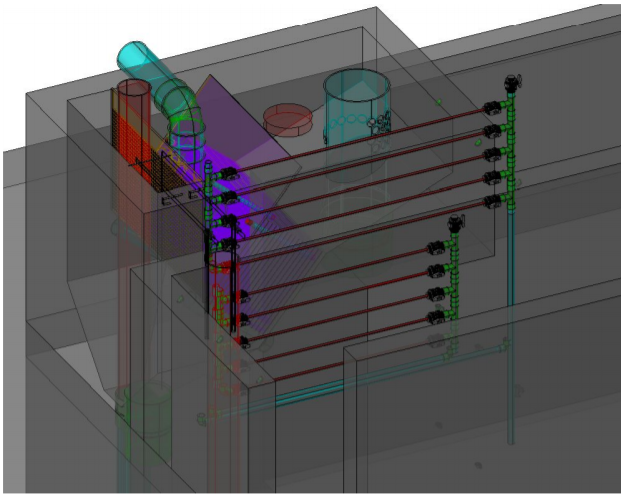

After the alum exits the dosing orifice it flows down through a rigid tube which then injects the alum over a rapid mix conduit which connects the entrance tank and the flocculator. The rapid mix tube has two orifices which create macro and micro eddies to ensure the uniform distribution of coagulant into the raw water.