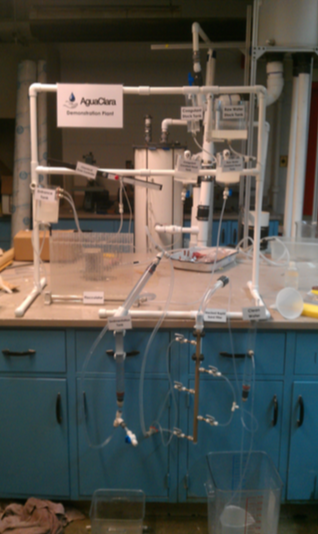

The team this semester focused mainly on rebuilding and improving the ram pump and its lab set-up. Major changes to the system from last semester include a more compact head loss system, higher overhead drive tank (to better simulate Honduras parameters), and an attempt to improve the air chamber design, In the end, the team was able to con- struct a working prototype that successfully pumped and delivered water through the entire head loss system. However, due to time constraints, the future team will have to make additional improvements to the system. They include a larger, encased recycling system, and more structural sup- ports to minimize instability. Although the initial run proved successful, additional testing could not be conducted due to computer malfunctions and again, time constraints. Had given the time, experimentation would be conducted regarding the ow rate, head loss, reliability, and scaling. Future teams can now focus on these experiments since the prototype is basically complete.