Eric Stucker and Jen Weidman

Abstract

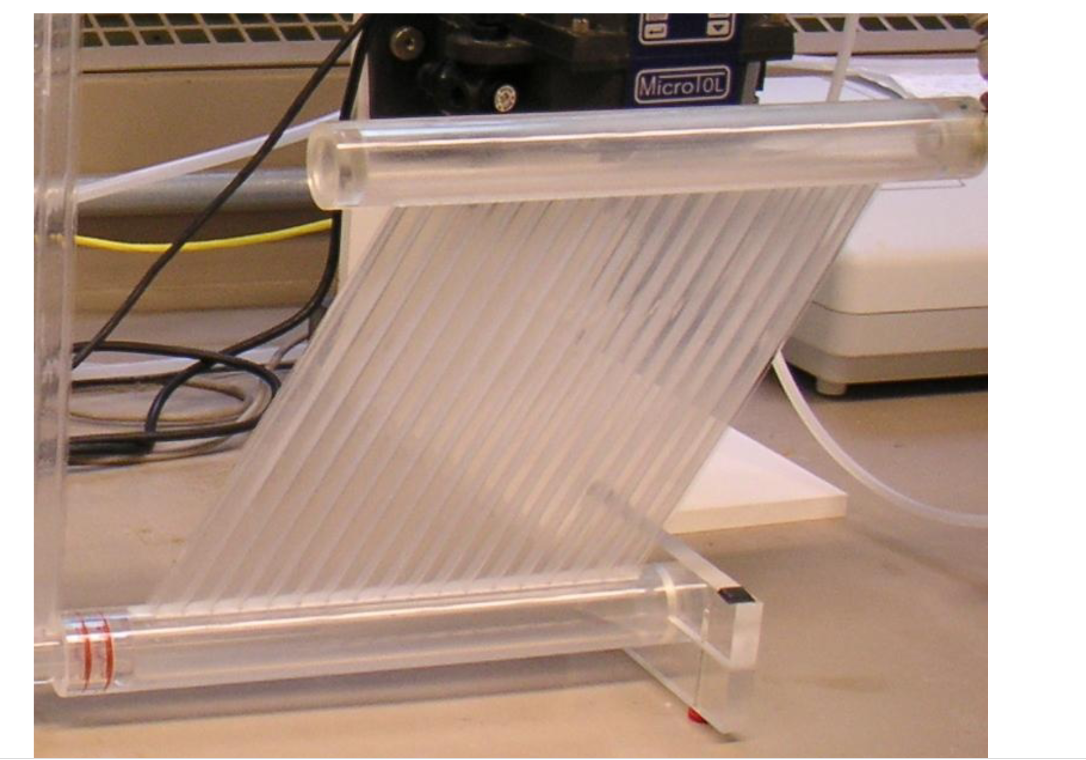

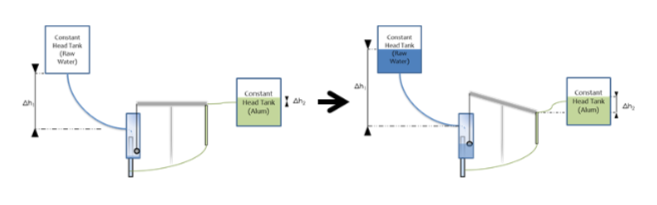

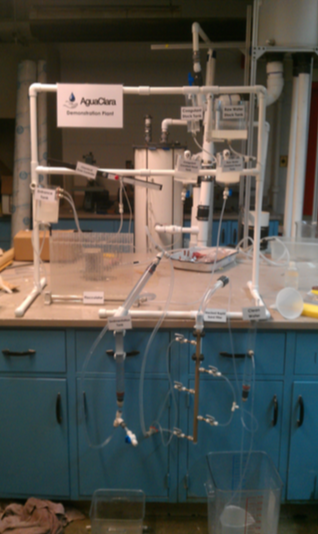

The demo plant team is responsible for design, construction, and troubleshooting of the AguaClara Demo Plant. The successful operation of this plant is crucial in order to demonstrate the inner workings of AguaClara plants to students, faculty, staff, community members, business partners, and potential sponsors. This spring semester, our research team has focused on creating one complete demo plant, and �fixing issues with that plant, such as an unreliable �flocculator and concerns with differences in head. This work included implementing and testing new �fittings for the stacked rapid sand �filter, conceptualizing and implementing a more efficient way to facilitate plant assembly and startup to those unfamiliar with it, resolving issues with improper coagulant dosing and head loss differences, and properly documenting all aspects of the plant so that future team members new to AguaClara (like us) would have much less difficulty familiarizing themselves with the Demo Plant.We also measured and adjusted plant �ow rates to match historical data and ensure smoother operation of the plant, and labeled tanks to further improve ease of operation of the plant. While we did not achieve our goal of fabricating new plants for future teams to use, we documented all the materials present, as well as those we need, and we provided detailed drawings for future construction.