Lily Siu

Abstract:

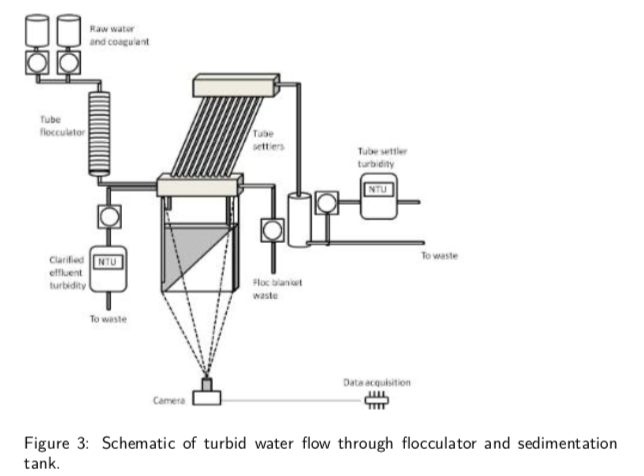

Our main objective we wish to accomplish this summer is to analyze the reinforcement configuration and structural strength of the sedimentation and flocculation tank walls. In the previous semester, the structural design team analyzed the structural capabilities of the columns and walls for the Alauca plant using various assumptions and load cases. The previous team analyzed the walls as closely spaced concrete columns. By modeling the walls as columns the flexural support provided by the horizontal reinforcement is unaccounted for, but it allowed for the use of the same tools and procedures that is used for beam analysis. We seek to attempt to validate the previous team’s calculations as well as suggesting methods to analyze the horizontal reinforcement in order to reduce over-designing. This report is meant to augment the Spring 2011 report.