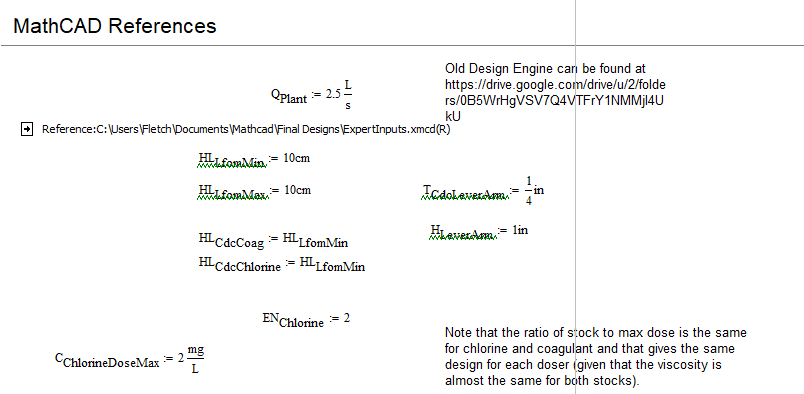

In the past few months, we have been continuing to develop our design tool, the AguaClara Infrastructure Design Engine (AIDE). To begin publicizing AIDE for broader use, we have prepared a few public-facing documents that give more insight into how the tool works.

The AguaClara textbook now contains a section that introduces AIDE, explains how we at AguaClara use AIDE, and describes how you can use AIDE to explore AguaClara technologies. The relevant section of the textbook can be found here. This section includes videos that guide you through an exploration of AIDE within Onshape, the CAD program that we use to design AguaClara plants.

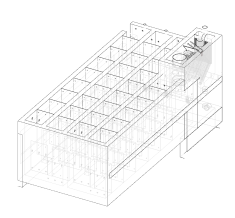

In addition, there are public demos available for various configurable components, which make up our customized water treatment plant designs. These public demos include a CAD model and an explanatory PDF. In the demo model, you can adjust certain parameters and quickly see how the new parameter values affect the physical model. The attached PDF describes the configurable component and defines the relevant parameters. This allows you to know more about the changes you are making and how they fit into the physics of the code integrated into the model.

We encourage you to explore our design tool and welcome feedback through this form.