Mihir Gupta, Kris LaPan, Rachel Proske

Abstract:

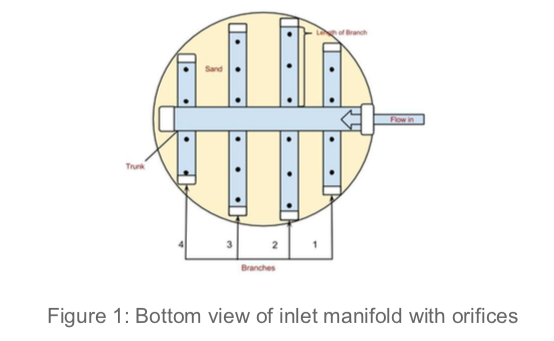

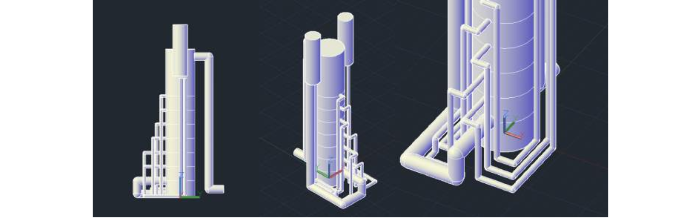

The use of filtration units for the treatment of drinking water is a common practice in engineering design. However these units are generally used for the treatment of large volumes of water. To improve upon this limitation, a stacked rapid sand filter was designed for low ow rates. Work for the semester began with an existing filtration unit which did not contain sand, due to predicted failure from large head losses in filtration and backwash. The existing design was modeled in AutoCAD 2013 to provide an illustration of the system. Updates to this drawing were completed and will continue to be as fabrication phases occur. One of the primary tasks was to develop a mathematical model in MathCAD to calculate the flows and head losses throughout the system. The model was completed for filtration and backwash, and includes calculations for both cycles with and without sand present. Hydraulic testing was completed to determine the head losses in filtration and backwash, risk of sand transport through the backwash pipe, and ow rates. These measurements and observations were compared with the mathematical model to determine its validity. According to head loss values obtained from the mathematical model, several changes were made to the filter prototype. Such fabrications included complete reconstruction of the backwash pipe, changing of valve types, and installation of NPT fittings and ball valves. Finally performance testing was completed to determine the effectiveness of the prototype in regards to decreasing effluent turbidity. Overall, it was determined that the filter prototype is highly effective at decreasing turbidity for several influent concentrations at the designed flow rate.