In 2005, the AguaClara program noticed that there weren’t any good options for treating turbid surface water for small cities, towns, and villages. We set out to develop water treatment plants that were designed from the ground up to produce high quality water at the lowest cost possible. After 23 plants built and continuously providing safe water on tap in Central America we have achieved that goal.

We developed a cost model for an AguaClara plant’s life cycle to enable comparison with other treatment options. The costing model gives an estimate for the cost per cubic meter of water treated for the lifetime of an AguaClara plant. This cost is comprehensive, including all construction and design costs of the plant as well as continuing operating costs.

Figure 1: Cost categories table

The costs for the plant are split into two general categories: initial project costs and lifetime operation costs. Included in the initial projects costs are: labor costs, initial material costs, design fees (including structural, electrical, architectural, and hydraulic designs), and initial training of operators. Lifetime operation costs include operator salaries, chemicals (coagulant and chlorine), ongoing training of operators (old & new), replacement parts, electricity, and minor maintenance.

Figure 2: Pie chart showing how the lifecycle cost is split up for a 25 L/s AguaClara plant that lasts 50 years.

As shown in the pie chart above, the majority of the costs go towards operator salaries. The next highest costs are for the chemicals, the coagulant and the chlorine. Then, the next highest costs are the initial project costs . The costs of minor maintenance, electricity (for lights), and replacement parts add up to less than 6% of the total cost of the plant. ACR hydraulic design fees are only 0.4% of the lifecycle cost because we have developed parametric designs for AguaClara plants and thus can design them quickly.

For our example estimate, we used data from AguaClara plants built by Agua Para el Pueblo in Honduras to inform our cost assumptions. We have adjusted for inflation so our costs are 2023 dollars. Our example estimate cost for a 25 L/s plant with a lifespan of 50 years would be $0.14 per cubic meter of water treated. We are looking for lifecycle costs of other available technologies (including conventional water treatment) used to treat surface water to compare to our estimate. If you have an estimate for another technology, please contact us.

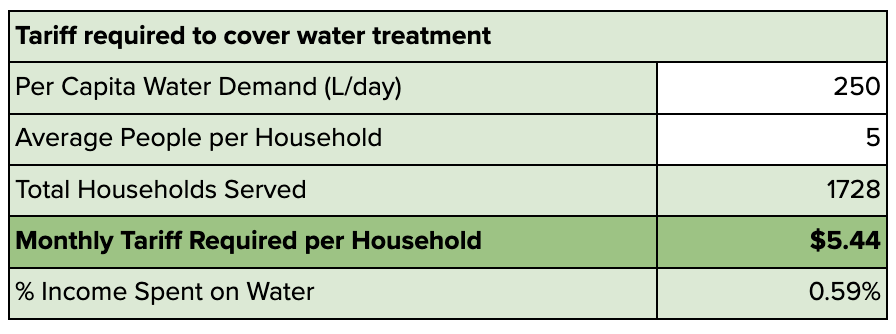

Figure 3: Table describing estimated required household tariffs.

What can we use this lifecycle cost data for? With this data, we were able to calculate what the monthly water tariff per household served would have to be in order to pay to replace the water treatment plant at the end of the lifetime of the water treatment plant. To put things into perspective, for a single income household of 5 people, less than 0.6% of the earner’s income would be spent on water treatment by an AguaClara plant.

Figure 4: Prices of water from utilities in Latin American countries (Plappally, Lienhard, 2012)

At the utility level, the cost of AguaClara water treatment is lower than the price of water provided by utilities throughout Latin America with the exception of El Salvador. The utility costs include source development, transmission, and distribution costs that would be in addition to the water treatment. The utility costs may be influenced by government subsidies or may not include full recovery of capital costs. We also expect potential partners to be able to compare our lifecycle costs with other water treatment plant technologies as one important factor in their decisions.