In early 2022, the Hospital de Especialidades Psiquiátrico Santa Rosita began conversations with Agua Para el Pueblo (APP) on bringing AguaClara technology to their facility. Santa Rosita is in the Valley of Amarateca just north of Tegucigalpa (Figure 1), the same valley where AguaClara plants serve the communities of Tamara, Cuatro Comunidades, Campo Verde, Las Moras, and Divina Providencia. In support of their initial project design and proposal efforts, APP requested that AguaClara Reach (ACR) develop a preliminary design for a 3 L/s plant including a filtration system for the Santa Rosita facility (Figure 2). This design request presented an opportunity for ACR to innovate on our existing filter designs, which included the Open Stacked Rapid Sand (OStaRS) filter and the Enclosed Stacked Rapid Sand (EStaRS) filter.

Figure 1: The Hospital de Especialidades Psiquiátrico Santa Rosita is located in the Valley of Amarateca.

Figure 2: Agua Para el Pueblo engineers, Minty Núñez (left) and Santiago Garcia (right) meet with representatives of the Hospital de Especialidades Psiquiátrico Santa Rosita to discuss providing safe water on tap with an AguaClara plant.

Open Stacked Rapid Sand Filters

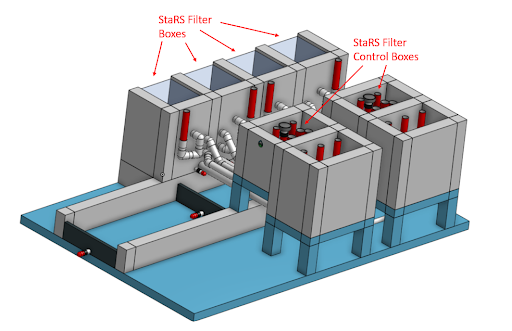

ACR’s AguaClara Infrastructure Design Engine (AIDE) in Onshape is able to generate designs that use Open Stacked Rapid Sand (OStaRS) filters between 16 and 80 L/s. An OStaRS filter typically consists of a hydraulic control box and a pair of filter boxes (Figure 3). The control box determines how much water flows to each filter box, while the filter boxes contain layers of sand that remove small particles from the water. However, at flow rates below 16 L/s, Open StaRS filters become too small for a mason to work inside the filter box. This constraint presented an opportunity to rethink the design process for low flow rate StaRS filters in order to meet the needs of the Santa Rosita facility.

Figure 3: An AguaClara 20 L/s Open Stacked Rapid Sand (OStaRS) Filter generated by AIDE containing a pair of filter boxes and the hydraulic control box that directs water into and receives the filtered water from each filter.

Enclosed Stacked Rapid Sand Filters

As an alternative to the OStaRS filter, which is constructed with concrete, the AguaClara Enclosed StaRS (EStaRS) filter is constructed with a large diameter PVC pipe. Smooth walled (non-corrugated) PVC pipes are available in sizes up to 12-inch diameter, which places a limit on the maximum filtration capacity for a single filter made of this material. In effect, the 3 L/s plant for Santa Rosita would require five EStaRS filters in parallel to meet its flow requirements (Figure 4).

Figure 4: A set of 5 Enclosed StaRS Filters designed with AIDE using 12-in PVC pipes.

ACR discussed this option with the team at APP and learned that the enclosed filters are not favorable because the numerous pipes and fittings result in a costly system. This created a conundrum because the Open StaRS filter design does not work for small scale plants, and the Enclosed StaRS filters are too costly.

The Innovation Process

With no readily available options for a filtration system that would be viable at low flow rates, it was time to rethink the original filter design. AguaClara’s design process is made possible with AIDE, which allows us to quickly and efficiently test concepts over a range of flow rates while accurately identifying possible construction challenges.

The goal of the first design iteration was to make a compact system with no valves. The result consisted of a platform containing the inlet and outlet control boxes directly connected to the filter boxes (Figure 5). This layout required fewer fittings and plumbing connections than the EStaRS filter, making it more affordable, but did not allow for the design to easily scale over a range of flow rates. As the design flow rate increased, the inlet and outlet pipes also grew larger in diameter, effectively reducing the space between them. This led to failure at higher flow rates because the pipes began to overlap with the space required by the concrete slab (Figure 6). Another downside to the design was the large size of the inlet control box, which, if implemented, would require a large volume of water to be wasted when transitioning the filters from backwash to filtration mode.

Figure 5: An early iteration of the Open Stacked Rapid Sand (StaRS) Filter with a platform in between the filter and control boxes.

Figure 6: The inlet and outlet pipes of an early OStaRS filter design iteration interfere with the concrete slab at larger flow rates as shown in the red box.

The goal of the next design iteration was to create compact control boxes with concrete slabs that were completely separate from the filter boxes. This eliminated the need to try to fit the slab between the inlet and outlet pipes. However, since all four filters in the design needed to be routed to a single control box, a unique plumbing path had to be created for each one. Routing the pipes for this design took a lot of time and several versions were created before finally settling on what seemed to be a reasonable layout (Figure 7). When the new design was shown to colleagues at APP, they advised that the significant number of angled pipes would make the design too difficult to construct. So, back to AIDE to optimize the piping layout!

Figure 7: An iteration of the Open Stacked Rapid Sand (StaRS) Filter with compact control boxes. Angled pipes are shown in the red box.

With APP’s feedback, ACR realized that the design should include as many straight pipes as possible. So for the next design, there is one control box for each pair of filters, which allows the pipe routes to be symmetric and therefore identical for all of the filters (Figure 8). This creates simple plumbing paths that are easy to construct (Figure 9).

Figure 8: Isometric view of a shallow OStaRS filter with the floor hidden to show piping connections.

Figure 9: Plan view of the filter control and filter boxes. A single filter control box (bottom) is connected to two filter boxes (top), resulting in straight, parallel pipes between them.

This new invention of a shallow Open StaRS filter extends the range of AguaClara filtration processes to serve communities with design flow rates as low as 3 L/s. The open design is an improvement from the previous Enclosed StaRS filter design because operators are able to look directly into the filter to monitor the process. Additionally, it provides a solution for communities that would like to upgrade their existing AguaClara plant to include a StaRS filter, as it can be built on the same concrete slab as the flocculator and clarifier, eliminating the need for additional excavation.

Figure 10: 3 L/s shallow OStaRS filter as part of a full AguaClara plant. The shallow filters can be built on the same slab as flocculator and clarifier.

The Santa Rosita preliminary design proposal demonstrates how new implementation challenges can spark design iteration and innovation, which is a shared process between AguaClara and our implementation partners. By using AIDE, we are able to quickly invent new designs and get feedback from partners who bring construction expertise. We hope you enjoyed learning about our innovation process!

Blog post authors: Emily Wood and Monroe Weber-Shirk