August Longo, Briana Li-Vidal, Michelle Cheng, Victoria Zhang

Abstract

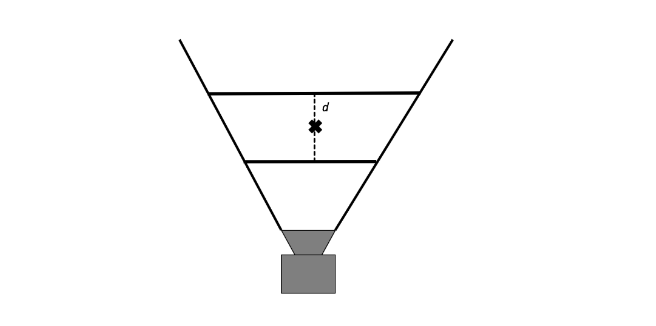

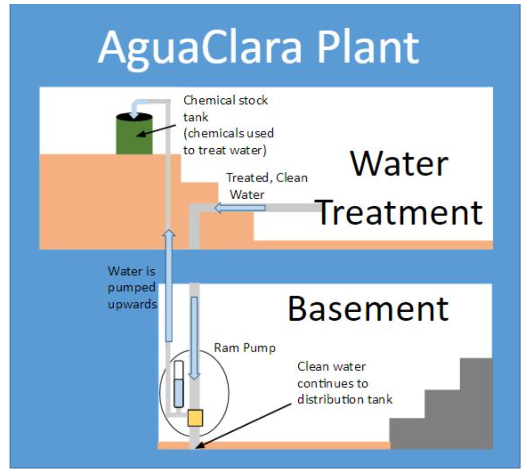

The Fluoride subteam seeks to develop a sustainable, inexpensive fluoride removal system for implementation in upcoming AguaClara plants located in India. After earning an EPA Phase II grant for the Spring 2016 fluoride removal reactor, the subteam seeks to improve fluoride purification by testing lab-scale systems to compare a single reactor with reactors in series. At the beginning of this semester, the subteam identified potential issues with floc buildup at the bottom of the reactor. Thus, a sloped plane bottom geometry was incorporated into the reactor system to encourage recirculation of the flocs. Additionally, experiments with high concentrations of PACl resulted in clogging of the apparatus due to PACl buildup. Clay was incorporated into the influent stream to abate this PACl buildup. Initial testing of fluoride removal with the updated one and two reactor systems provided results that seem to indicate slightly better fluoride removal efficiency with two reactors, but more data collected by future testing is required to make a concrete conclusion.