Tanya Cabrito, Jae Lim, Cosme Somogyi

Abstract:

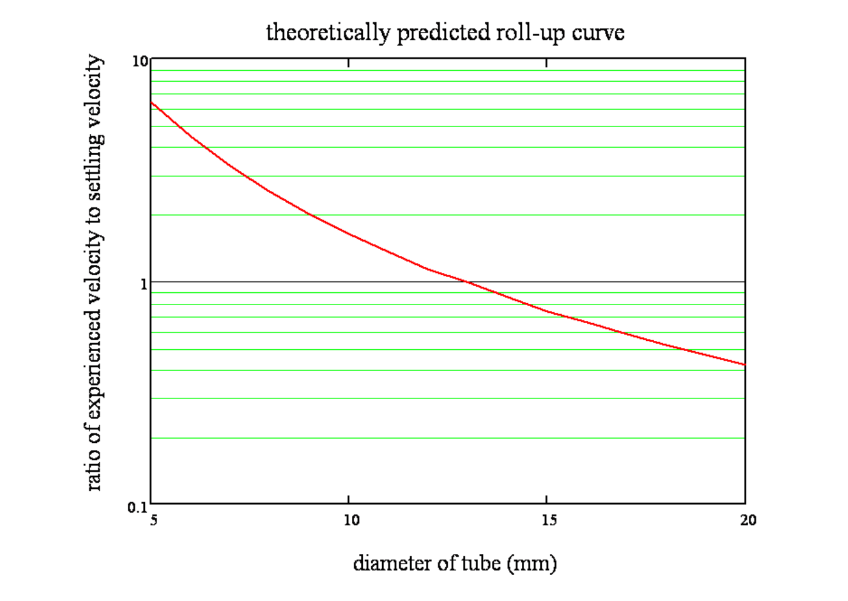

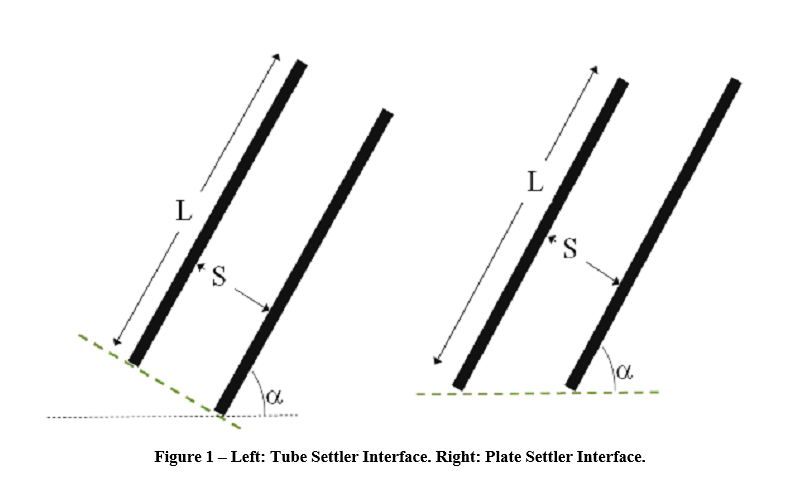

The goal of the Plate Settler Spacing Team (PSS) is to study the lamellar sedimentation process in plate settlers and the efficiency of the removal of flocculated particles and establish improved guidelines for plate settler spacing. The traditional guidelines for plate settlers state that the spacing between plates cannot be less than 5 cm and little to no justification can be found for this. The team's results show that performance in accordance with the US drinking water standard of 0.3 NTU can be achieved with spacings smaller than 5 cm. Also, all but one of the experiments meet the World Health Organization standard of 5 NTU. For AguaClara plants, having smaller spacings between plate settlers allow the sedimentation tank to be shallower and therefore cheaper. Smaller spacings also allow for increased head loss across the plate settlers. This would help even out the distribution of flow in AC plants and allow the plate settler system to function at its design capture velocity of 0.12 mm/s throughout. The team had finished velocity gradient experiments with a clay aluminum hydroxide system; however, a recently discovered mistake in documentation caused the team to reassess the data collected this semester and more tube trials must be run. Due to this error, the team changed the capture velocity for the velocity gradient from 0.12 mm/s to 0.10 mm/s. The major tasks completed by the Fall 2010 PSS team are catching a documentation error that happened at the end of Spring 2010, studying the effects of high velocity gradients and floc rollup on plate settler performance, developing a macro that significantly facilitates data analysis and a plate settler dynamics model that may better shed light into processes governing plate settler performance.